- 中文

-

+86-18537242761

-

energy-saving and low-consumption

Save 35% electrode consumption compared to AC furnaces and 15-20% compared to AC furnaces, without the need for reactive power compensation devices, greatly reducing the operating costs of enterprises

-

Solution service

Provide customers with metallurgical process technology solutions and formulas, rare and precious metal enrichment process technology solutions and formulas, and provide full technical support and follow-up throughout the process

-

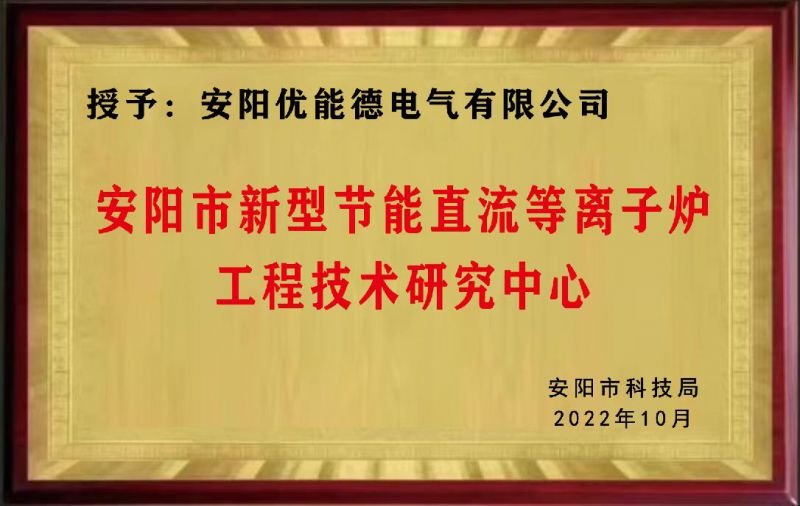

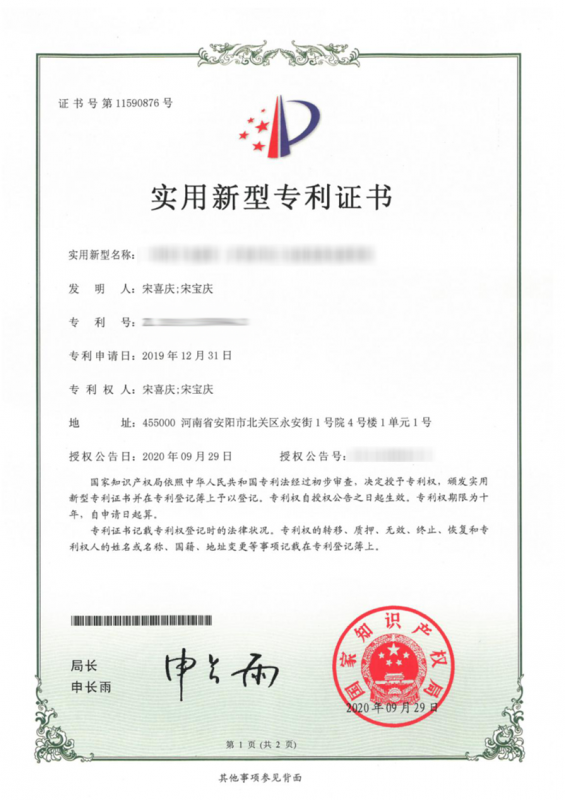

R&D capability

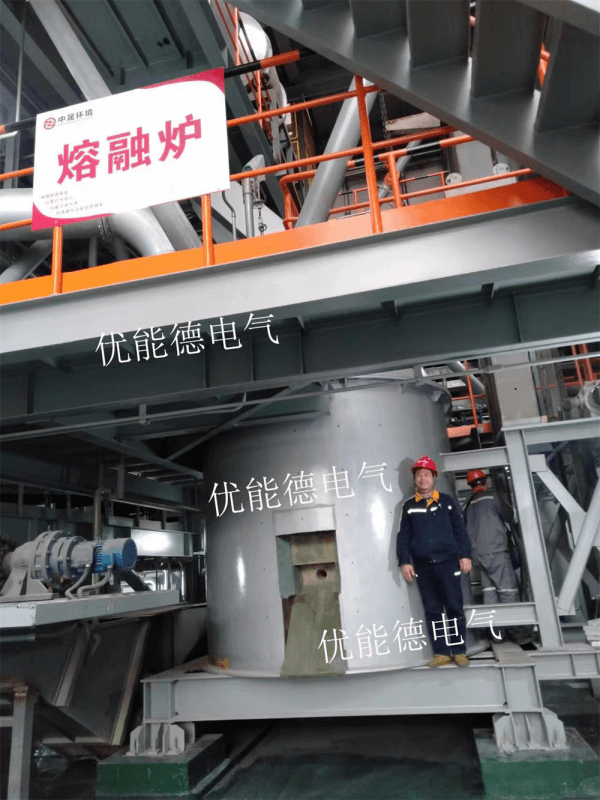

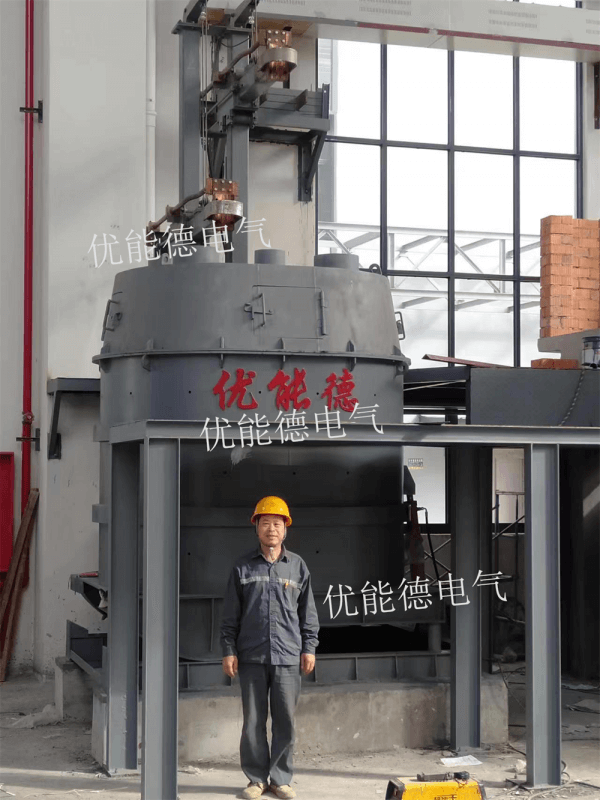

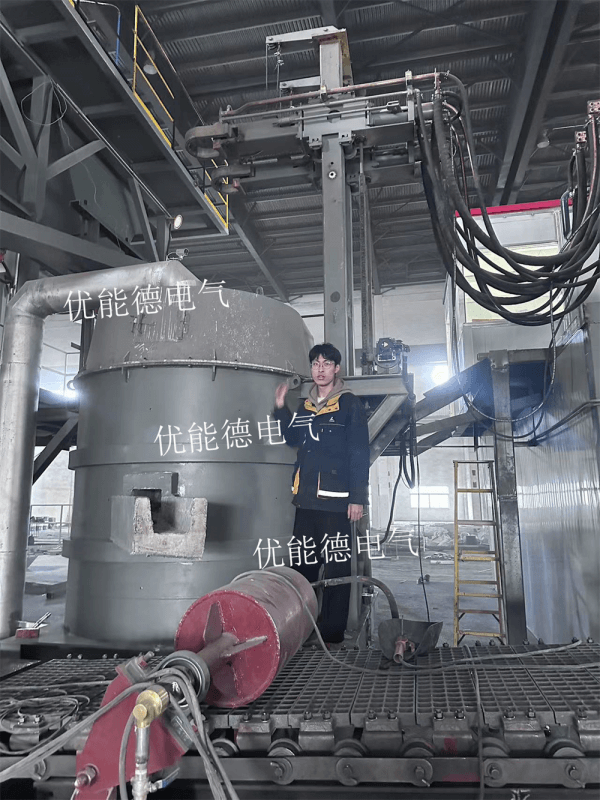

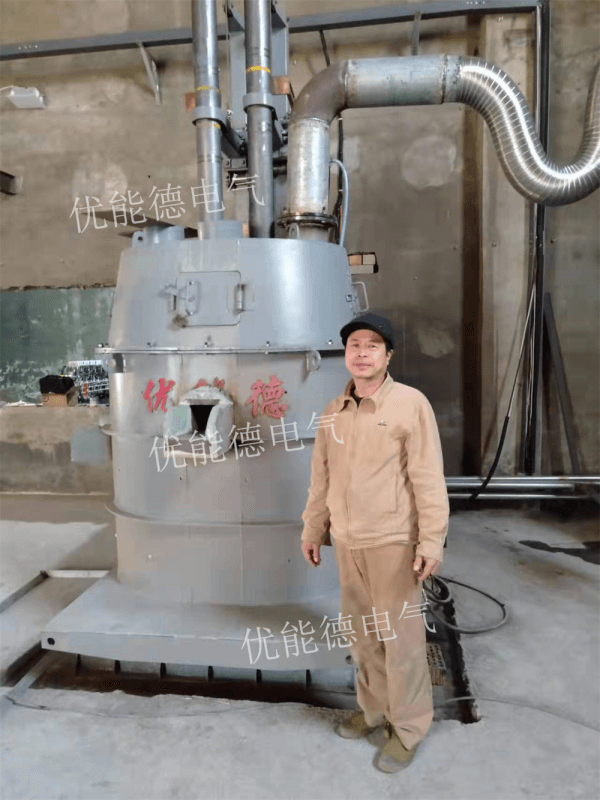

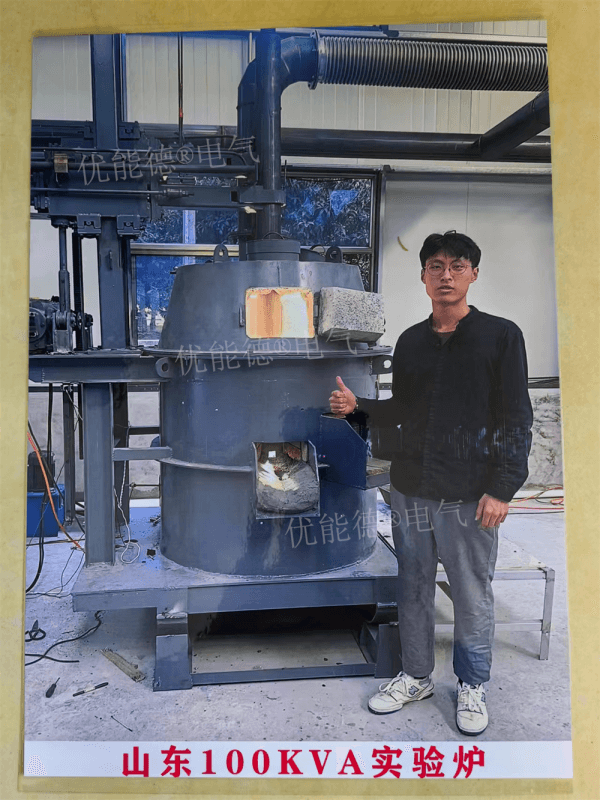

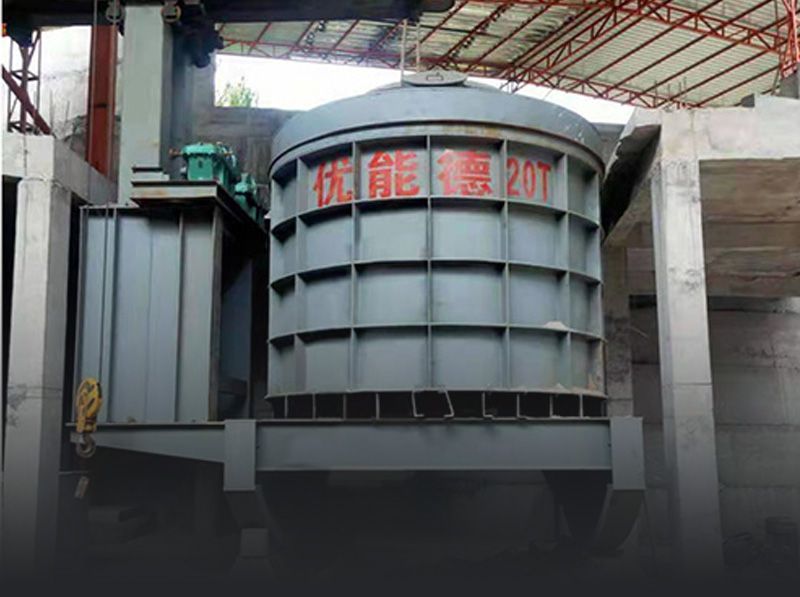

Anyang Youneng De Electrical Co., Ltd. independently develops, designs, manufactures, installs, and debugs DC plasma melting furnaces, high-power DC power supplies, and equipment for non-toxic treatment of solid and hazardous waste

Application range

The types of materials that can be melted are: metal alloys, minerals, tailings slag, solid wastes, hazardous wastes, various melting wastes, and dust. -Services.

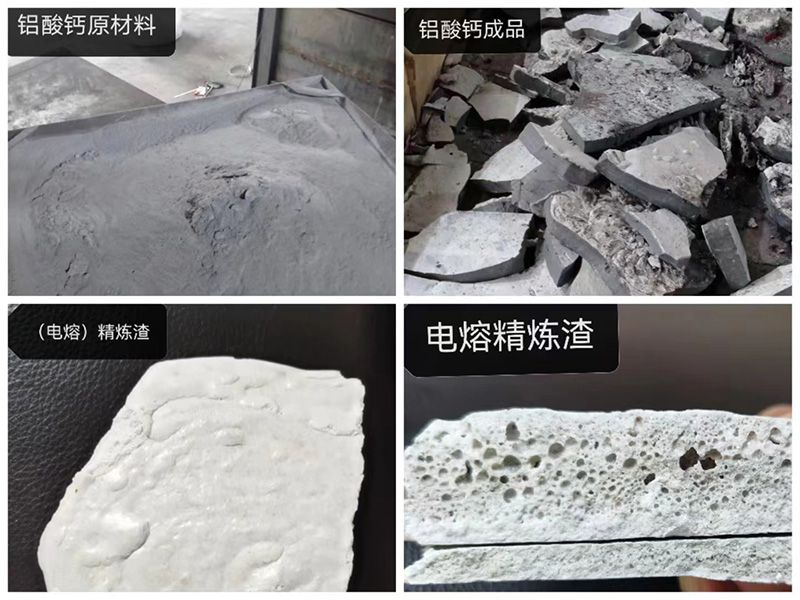

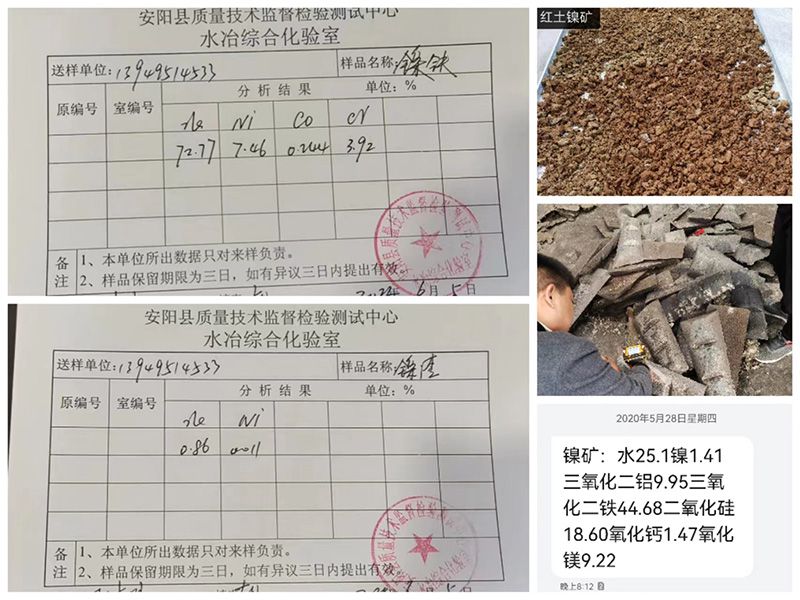

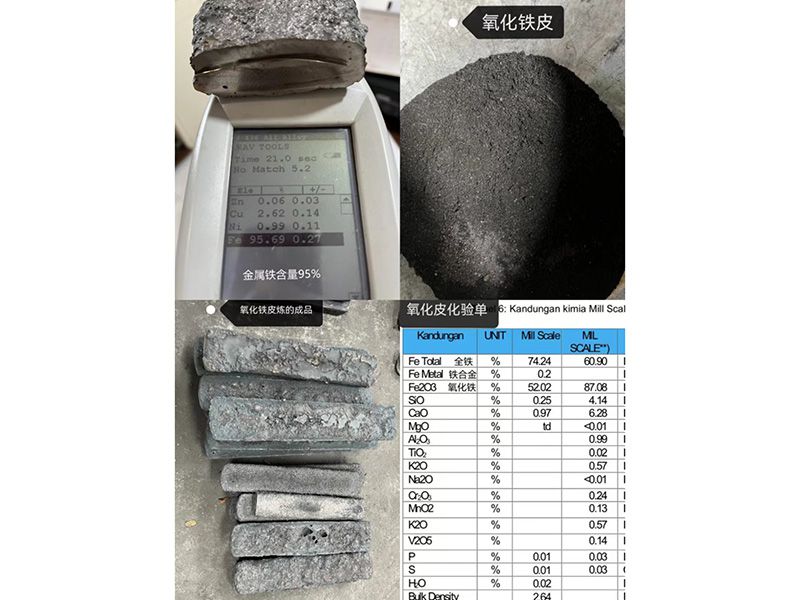

The process of extracting and enriching rare and precious metals from raw ore, catalysts, and industrial solid waste is mature and has a high yield. The yield of metal silicon cutting mud and metal silicon silicon slag refining 75 # ferrosilicon is high. The direct melting of scrap circuit boards into the furnace has a high recovery rate for non-ferrous metals. The mature process of calcium aluminate smelting produces high-quality products.

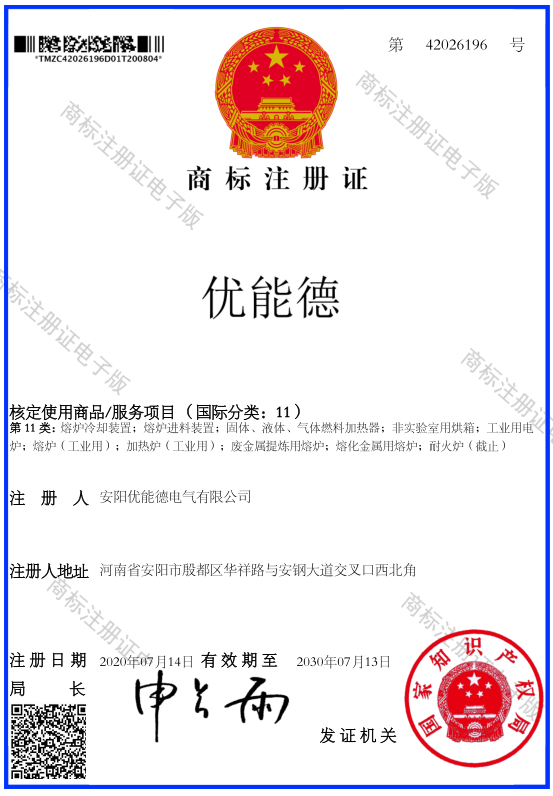

Anyang Youneng De Electric Co., Ltd. Luoyang Youneng De Electric Co., Ltd. is a high-tech enterprise engaged in the research, design, and manufacturing of (new, energy-saving, multifunctional) DC plasma melting furnaces, high-power DC power supplies, and equipment for non-toxic treatment of solid and hazardous waste.

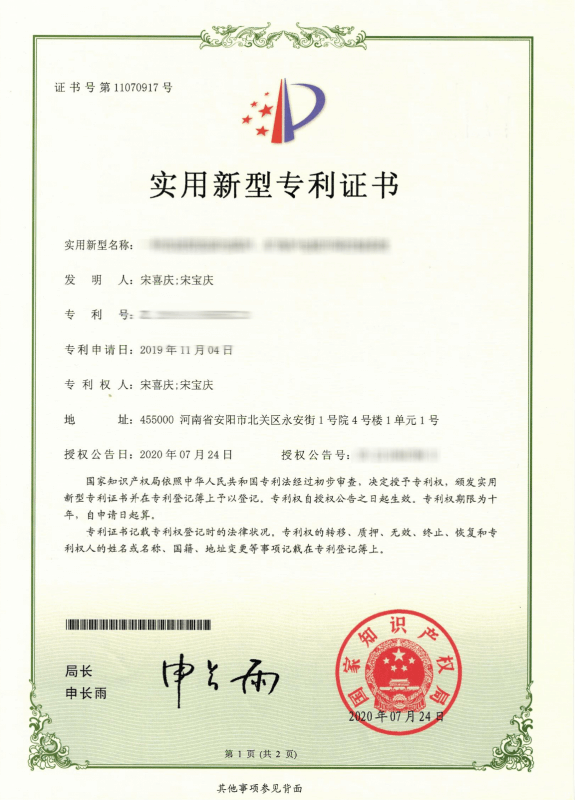

Our company adheres to independent innovation and pioneering spirit, and has achieved 20 * * projects related to DC plasma melting furnaces. The design and manufacturing capacity of the equipment ranges from 50kVA to 30000kVA.

The process of extracting and enriching rare and precious metals from raw ore, catalysts, and industrial solid waste is mature and has a high yield. The yield of metal silicon cutting mud and metal silicon silicon slag refining 75 # ferrosilicon is high. The direct melting of scrap circuit boards into the furnace has a high recovery rate for non-ferrous metals. The mature process of calcium aluminate smelting produces high-quality products.

The circuit adopts the high-speed railway rectification working system of * *. No interference to the power grid. Widely applicable, the temperature of the arc core can reach up to 10000 ℃, and the temperature of the arc flame is 4000 ℃.

The types of elements that can be smelted include: iron, copper, nickel, cobalt, lead, zinc, tin, antimony, bismuth, gold, silver, chromium, molybdenum, magnesium, manganese, tantalum, niobium, platinum, rhodium, palladium, vanadium, titanium, iridium and other metals.

The types of raw materials that can be smelted include metal alloys, ores, tailings, solid waste, hazardous waste, various smelting waste residues, dust removal ash, and other materials.