Introduction to Electric Arc Furnaces

Electric arc furnaces on the market are generally divided into two types in terms of current form: DC arc furnaces and AC arc furnaces.

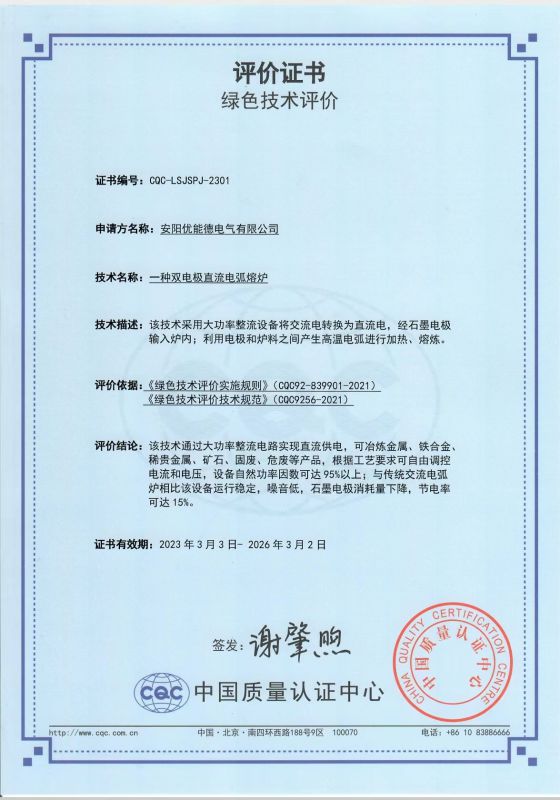

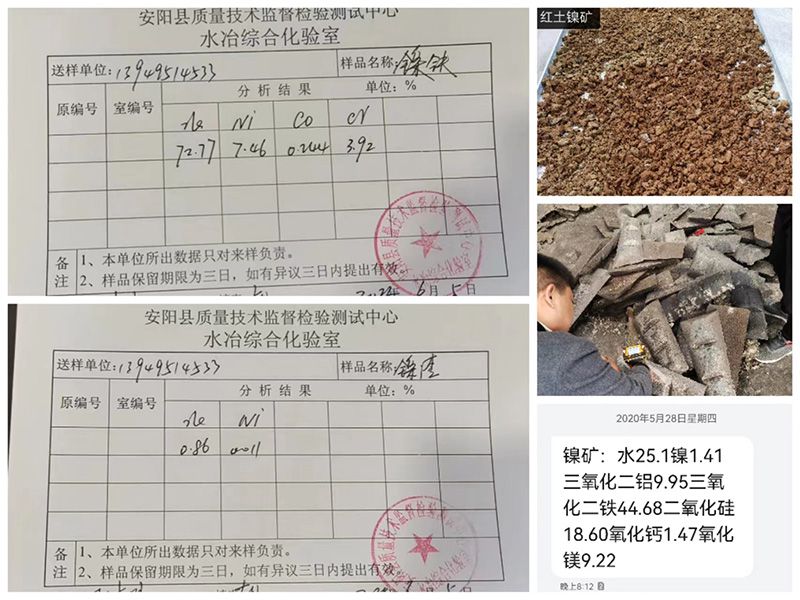

. Each type of electric arc furnace is divided into open arc furnace (where the arc light is exposed outside the raw material, also known as an electric arc furnace) and submerged arc furnace (where the arc light is buried inside the raw material, also known as a submerged arc furnace) based on the length and state of the arc light. Let's talk about AC arc furnaces first. The structure of the AC furnace is relatively simple, with three-phase AC connected to three electrodes and no complex rectification circuit, so the cost is relatively low. Price is the advantage of communication furnaces. However, due to the inherent characteristics of alternating current, the arc light of an AC furnace is constantly repeating the process of starting and extinguishing arcs, and then starting and extinguishing arcs again, which means that the arc light is unstable. Moreover, the power factor of the AC furnace is relatively low, averaging 0.85, which means that 15% of the electrical energy is wasted. It is necessary to add reactive power compensation devices to increase it to 0.9. At the same time, each set of communication furnaces is strictly calculated and designed according to the material conditions, and you cannot arbitrarily change the properties of the raw materials. For example, when designing, the grade of iron in your raw material was 55. Now that the furnace has produced it and you have obtained better materials, the grade of iron has increased to 80, and your furnace cannot be used anymore. You must lower the grade to around 55. The arc length of the communication furnace cannot be changed arbitrarily. For the communication furnace, the open arc and buried arc cannot be changed arbitrarily, and only one can be selected. Let's talk about the DC furnace. DC furnaces require rectification circuits to convert alternating current into direct current. In direct current conditions, the arc will not start or stop repeatedly and can remain in a stable state. The power factor of a DC furnace can generally reach 0.9 or above. DC furnaces are divided into single electrode furnaces and double electrode furnaces based on the number of electrodes. There is only one graphite electrode above the single electrode furnace, which is the negative electrode, while the positive electrode is located at the bottom of the furnace and is called the bottom electrode. The positive and negative graphite electrodes of the dual electrode furnace are both located above the furnace. Most DC furnaces on the market are single electrode furnaces. But a serious problem with single electrode furnaces is that the bottom electrode is prone to damage. Due to the fact that the bottom electrode must come into contact with the bottom graphite brick, which in turn must come into contact with the raw materials inside the furnace, the temperature inside the furnace is very high during the smelting process. In continuous production, the temperature of the graphite brick may reach over 1000 ℃, which leads to the melting of the bottom electrode at high temperatures. If the bottom electrode is melted, it cannot be used anymore. At this time, it is necessary to replace the bottom electrode and rebuild the refractory material of the furnace lining. If it's a small experimental furnace, replacing it once won't have much impact. If it is a large furnace for industrial production, it takes at least 15 days to replace the bottom of the furnace, which will cause significant losses. To solve this problem, we have devoted ourselves to developing dual electrode devices. Thoroughly solved the problem of electrode melting at the bottom of the furnace. However, due to the different temperatures at the bottom of the positive and negative electrodes, over time, there may be a situation where one side of the raw material has melted while the other side has not melted. To this end, we have developed a positive negative electrode conversion system that switches electrode polarity at regular intervals to achieve uniform melting temperature. Our equipment has a power factor of at least 0.95, which sounds a bit higher than 0.9, but the technical content is different. Just like the thermal efficiency of a car engine, when the thermal efficiency of other brands' engines is only 0.35-0.37, Toyota engines can reach 0.4, which requires a lot of time and funding to research, and this is the technological gap. The advantage of our large device is its highly flexible operation. Our equipment can change the arc length arbitrarily, achieving both visible and buried arcs. The current can be adjusted arbitrarily without changing the arc length. Therefore, our equipment can melt any material you can find. You can smelt any ore, any metal, and solid and hazardous waste. For example, if you think smelting ferroalloys makes money now, you can smelt ferroalloys. In the future, when the market changes and smelting precious metal ores makes money, you can immediately smelt precious metals without changing equipment.Introduction to Electric Arc Furnaces

Electric arc furnaces on the market are generally divided into two types in terms of current form: DC arc furnaces and AC arc furnaces.

. Each type of electric arc furnace is divided into open arc furnace (where the arc light is exposed outside the raw material, also known as an electric arc furnace) and submerged arc furnace (where the arc light is buried inside the raw material, also known as a submerged arc furnace) based on the length and state of the arc light. Let's talk about AC arc furnaces first. The structure of the AC furnace is relatively simple, with three-phase AC connected to three electrodes and no complex rectification circuit, so the cost is relatively low. Price is the advantage of communication furnaces. However, due to the inherent characteristics of alternating current, the arc light of an AC furnace is constantly repeating the process of starting and extinguishing arcs, and then starting and extinguishing arcs again, which means that the arc light is unstable. Moreover, the power factor of the AC furnace is relatively low, averaging 0.85, which means that 15% of the electrical energy is wasted. It is necessary to add reactive power compensation devices to increase it to 0.9. At the same time, each set of communication furnaces is strictly calculated and designed according to the material conditions, and you cannot arbitrarily change the properties of the raw materials. For example, when designing, the grade of iron in your raw material was 55. Now that the furnace has produced it and you have obtained better materials, the grade of iron has increased to 80, and your furnace cannot be used anymore. You must lower the grade to around 55. The arc length of the communication furnace cannot be changed arbitrarily. For the communication furnace, the open arc and buried arc cannot be changed arbitrarily, and only one can be selected. Let's talk about the DC furnace. DC furnaces require rectification circuits to convert alternating current into direct current. In direct current conditions, the arc will not start or stop repeatedly and can remain in a stable state. The power factor of a DC furnace can generally reach 0.9 or above. DC furnaces are divided into single electrode furnaces and double electrode furnaces based on the number of electrodes. There is only one graphite electrode above the single electrode furnace, which is the negative electrode, while the positive electrode is located at the bottom of the furnace and is called the bottom electrode. The positive and negative graphite electrodes of the dual electrode furnace are both located above the furnace. Most DC furnaces on the market are single electrode furnaces. But a serious problem with single electrode furnaces is that the bottom electrode is prone to damage. Due to the fact that the bottom electrode must come into contact with the bottom graphite brick, which in turn must come into contact with the raw materials inside the furnace, the temperature inside the furnace is very high during the smelting process. In continuous production, the temperature of the graphite brick may reach over 1000 ℃, which leads to the melting of the bottom electrode at high temperatures. If the bottom electrode is melted, it cannot be used anymore. At this time, it is necessary to replace the bottom electrode and rebuild the refractory material of the furnace lining. If it's a small experimental furnace, replacing it once won't have much impact. If it is a large furnace for industrial production, it takes at least 15 days to replace the bottom of the furnace, which will cause significant losses. To solve this problem, we have devoted ourselves to developing dual electrode devices. Thoroughly solved the problem of electrode melting at the bottom of the furnace. However, due to the different temperatures at the bottom of the positive and negative electrodes, over time, there may be a situation where one side of the raw material has melted while the other side has not melted. To this end, we have developed a positive negative electrode conversion system that switches electrode polarity at regular intervals to achieve uniform melting temperature. Our equipment has a power factor of at least 0.95, which sounds a bit higher than 0.9, but the technical content is different. Just like the thermal efficiency of a car engine, when the thermal efficiency of other brands' engines is only 0.35-0.37, Toyota engines can reach 0.4, which requires a lot of time and funding to research, and this is the technological gap. The advantage of our large device is its highly flexible operation. Our equipment can change the arc length arbitrarily, achieving both visible and buried arcs. The current can be adjusted arbitrarily without changing the arc length. Therefore, our equipment can melt any material you can find. You can smelt any ore, any metal, and solid and hazardous waste. For example, if you think smelting ferroalloys makes money now, you can smelt ferroalloys. In the future, when the market changes and smelting precious metal ores makes money, you can immediately smelt precious metals without changing equipment.