-

Electric arc furnace steelmaking process!http://www.ayynd.com/ Keywords:2022-02-15

Electric arc furnace steelmaking process!http://www.ayynd.com/ Keywords:2022-02-15 -

Development background of electric arc furnace steelmaking!http://www.ayynd.com/ Keywords:2022-02-10

Development background of electric arc furnace steelmaking!http://www.ayynd.com/ Keywords:2022-02-10 -

What are the advantages of electric arc furnaces over medium frequency furnaces?http://www.ayynd.com/ Keywords:DC ore blast furnace2022-02-05

What are the advantages of electric arc furnaces over medium frequency furnaces?http://www.ayynd.com/ Keywords:DC ore blast furnace2022-02-05 -

How to classify electric arc furnaces?How to classify electric arc furnaces? As we mentioned before,2022-01-24

How to classify electric arc furnaces?How to classify electric arc furnaces? As we mentioned before,2022-01-24 -

What are the key functions of a ladle refining furnace?What are the key functions of a ladle refining furnace? http://www.ayynd.com/ Keywords:2022-01-21

What are the key functions of a ladle refining furnace?What are the key functions of a ladle refining furnace? http://www.ayynd.com/ Keywords:2022-01-21 -

What are the common types of electric arc furnaces?What are the common types of electric arc furnaces? We have talked about many types of electric arc furnaces before. So, what are the common types of electric arc furnaces? Let's learn about it together! Three phase electric arc furnaceThis type of electric arc furnace uses three-phase AC power as the switching power supply, and generally uses carbon electrodes or high-purity graphite electrodes. The arc is generated between the electrode and the melted furnace material, and the furnace material is immediately heated by the arc. The length of the arc is adjusted by adjusting the electrode. To improve the quality of melting, large and medium-sized electric arc furnaces are equipped with electromagnetic stirrers at the bottom of the furnace, forcing the molten metal material in the furnace to circulate in a certain direction. Electric arc furnaces weighing over 50 tons are often equipped with furnace wall rotating structures, which can rotate up and down a certain angle of view, making the furnace material evenly heated. When the metal material liquid is discharged from the furnace, the furnace wall can tilt. Three phase electric arc furnaces are widely used for ironmaking. Self consuming electric arc furnaceThe electrodes of this type of electric arc furnace are the raw materials for the melted steel.. During melting, as the steel raw material continues to melt, the electrode continues to lower. The melted steel droplets enter the red copper cylindrical clamp pot with cooling water and solidify into cast steel parts. This type of furnace is suitable for melting carbon steel. The self consuming arc furnace used for melting active metals such as titanium, zirconium, tungsten, molybdenum, tantalum, niobium, and silicide metal materials is generally operated under a vacuum pump, hence it is called a vacuum pump self consuming arc furnace. Single phase electric arc furnaceThis type of electric arc furnace uses single-phase asynchronous motors for power distribution.. The furnace charge is indirectly heated by the arc. Single phase electric arc furnaces are commonly used for melting copper and alloy copper. Resistive arc furnaceThe furnace structure is similar to that of ironmaking arc furnace.. During work, an arc is generated beneath the electrode buried in the furnace material. In addition to the heat generated by the arc between the electrode and the furnace material, the current generated by the furnace material resistor also causes a significant amount of heat. This type of electric arc furnace is suitable for iron ore smelting plants and is therefore also known as a submerged arc furnace. Alright, the above is the relevant information about electric arc furnaces. For more information about electric arc furnaces, please follow the official website:=“ http://www.ayynd.com/ " target="_self"> http://www.ayynd.com/ Keywords:2022-01-17

What are the common types of electric arc furnaces?What are the common types of electric arc furnaces? We have talked about many types of electric arc furnaces before. So, what are the common types of electric arc furnaces? Let's learn about it together! Three phase electric arc furnaceThis type of electric arc furnace uses three-phase AC power as the switching power supply, and generally uses carbon electrodes or high-purity graphite electrodes. The arc is generated between the electrode and the melted furnace material, and the furnace material is immediately heated by the arc. The length of the arc is adjusted by adjusting the electrode. To improve the quality of melting, large and medium-sized electric arc furnaces are equipped with electromagnetic stirrers at the bottom of the furnace, forcing the molten metal material in the furnace to circulate in a certain direction. Electric arc furnaces weighing over 50 tons are often equipped with furnace wall rotating structures, which can rotate up and down a certain angle of view, making the furnace material evenly heated. When the metal material liquid is discharged from the furnace, the furnace wall can tilt. Three phase electric arc furnaces are widely used for ironmaking. Self consuming electric arc furnaceThe electrodes of this type of electric arc furnace are the raw materials for the melted steel.. During melting, as the steel raw material continues to melt, the electrode continues to lower. The melted steel droplets enter the red copper cylindrical clamp pot with cooling water and solidify into cast steel parts. This type of furnace is suitable for melting carbon steel. The self consuming arc furnace used for melting active metals such as titanium, zirconium, tungsten, molybdenum, tantalum, niobium, and silicide metal materials is generally operated under a vacuum pump, hence it is called a vacuum pump self consuming arc furnace. Single phase electric arc furnaceThis type of electric arc furnace uses single-phase asynchronous motors for power distribution.. The furnace charge is indirectly heated by the arc. Single phase electric arc furnaces are commonly used for melting copper and alloy copper. Resistive arc furnaceThe furnace structure is similar to that of ironmaking arc furnace.. During work, an arc is generated beneath the electrode buried in the furnace material. In addition to the heat generated by the arc between the electrode and the furnace material, the current generated by the furnace material resistor also causes a significant amount of heat. This type of electric arc furnace is suitable for iron ore smelting plants and is therefore also known as a submerged arc furnace. Alright, the above is the relevant information about electric arc furnaces. For more information about electric arc furnaces, please follow the official website:=“ http://www.ayynd.com/ " target="_self"> http://www.ayynd.com/ Keywords:2022-01-17 -

What are the main characteristics of electric arc furnaces?http://www.ayynd.com/ Keywords:2022-01-12

What are the main characteristics of electric arc furnaces?http://www.ayynd.com/ Keywords:2022-01-12 -

The main purpose of a mineral heat furnace!The main purpose of a mineral thermal furnace2021-12-31

The main purpose of a mineral heat furnace!The main purpose of a mineral thermal furnace2021-12-31 -

Analysis and Introduction of the Causes of Electrode Accidents in Mineral Heating Furnaces!Electrode safety accidents are an application2021-12-30

Analysis and Introduction of the Causes of Electrode Accidents in Mineral Heating Furnaces!Electrode safety accidents are an application2021-12-30 -

The basic structure of a mineral heat furnace!Basic Structure of Mineral Heat Furnace2021-12-29

The basic structure of a mineral heat furnace!Basic Structure of Mineral Heat Furnace2021-12-29 -

What is the cost of steelmaking in a blast furnace?http://www.ayynd.com/ Keywords:2021-12-28

What is the cost of steelmaking in a blast furnace?http://www.ayynd.com/ Keywords:2021-12-28 -

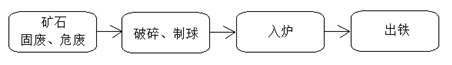

New Concept · Short Process · Non Blast Furnace Smelting1, Craft IntroductionA new process for direct reduction ironmaking of low-grade iron containing materials (containing over 35% iron). The carbon emissions are 50-60% lower than traditional blast furnace processes. Solution 1: Use our company's DC plasma electric furnace to directly melt the pressed balls into the furnace (with a power consumption of about 900 kWh per ton of raw material). Option 2: Preheat natural gas to 1000 ℃ (about 50m ³ of natural gas is consumed for one ton of raw material). Then it is melted in a DC plasma electric furnace (with a power consumption of about 390 kWh per ton of raw material).2021-12-28

New Concept · Short Process · Non Blast Furnace Smelting1, Craft IntroductionA new process for direct reduction ironmaking of low-grade iron containing materials (containing over 35% iron). The carbon emissions are 50-60% lower than traditional blast furnace processes. Solution 1: Use our company's DC plasma electric furnace to directly melt the pressed balls into the furnace (with a power consumption of about 900 kWh per ton of raw material). Option 2: Preheat natural gas to 1000 ℃ (about 50m ³ of natural gas is consumed for one ton of raw material). Then it is melted in a DC plasma electric furnace (with a power consumption of about 390 kWh per ton of raw material).2021-12-28

- 中文

-

+86-18537242761