-

Basic principles and applications of electric arc furnace!The basic principles and applications of electric arc furnaces! Electric arc furnace is a device that uses the principle of electric arc heating for smelting, widely used in fields such as metal smelting and slag processing. The following is a detailed introduction to the basic principles and applications of electric arc furnaces. The basic principle of an electric arc furnace is to use current to form an arc through electrodes, and heat and melt metals or other materials through the high temperature generated by the arc. After the formation of an arc, its temperature can reach thousands of degrees Celsius, enough to rapidly melt the metal. Usually, the electrodes of an electric arc furnace are made of conductive materials such as graphite, while metal materials serve as carriers of current. Application FieldsMetal Smelting: Electric arc furnaces have a wide range of applications in metal smelting, especially in the process of recycling scrap metals and producing alloys.. By adjusting the working conditions of the electric arc furnace, smelting and alloying of different metals can be achieved, improving the purity and quality of the metals. Waste disposal: Electric arc furnaces are also commonly used to process various types of waste, including discarded electronic equipment, used vehicle parts, etc. Through the action of high-temperature electric arcs, organic and inorganic substances in waste can be effectively decomposed and treated, reducing environmental pollution. Slag processing: In the metallurgical process, the slag produced is an important byproduct. Electric arc furnaces can be used to process slag into recyclable materials, reducing resource waste. Special alloy production: The preparation of some special alloys requires extremely high temperatures and precise control, and the high-temperature characteristics of electric arc furnaces make them an ideal choice for the production of such alloys.2023-11-20

Basic principles and applications of electric arc furnace!The basic principles and applications of electric arc furnaces! Electric arc furnace is a device that uses the principle of electric arc heating for smelting, widely used in fields such as metal smelting and slag processing. The following is a detailed introduction to the basic principles and applications of electric arc furnaces. The basic principle of an electric arc furnace is to use current to form an arc through electrodes, and heat and melt metals or other materials through the high temperature generated by the arc. After the formation of an arc, its temperature can reach thousands of degrees Celsius, enough to rapidly melt the metal. Usually, the electrodes of an electric arc furnace are made of conductive materials such as graphite, while metal materials serve as carriers of current. Application FieldsMetal Smelting: Electric arc furnaces have a wide range of applications in metal smelting, especially in the process of recycling scrap metals and producing alloys.. By adjusting the working conditions of the electric arc furnace, smelting and alloying of different metals can be achieved, improving the purity and quality of the metals. Waste disposal: Electric arc furnaces are also commonly used to process various types of waste, including discarded electronic equipment, used vehicle parts, etc. Through the action of high-temperature electric arcs, organic and inorganic substances in waste can be effectively decomposed and treated, reducing environmental pollution. Slag processing: In the metallurgical process, the slag produced is an important byproduct. Electric arc furnaces can be used to process slag into recyclable materials, reducing resource waste. Special alloy production: The preparation of some special alloys requires extremely high temperatures and precise control, and the high-temperature characteristics of electric arc furnaces make them an ideal choice for the production of such alloys.2023-11-20 -

Innovative Technologies and Future Development Trends of Electric Arc Furnaces!Innovative Technologies and Future Development Trends of Electric Arc Furnaces! As a key technology in the smelting field, electric arc furnace is constantly innovating and improving with the continuous development of technology. The following is a detailed introduction to innovative technologies and future development trends of electric arc furnaces. Innovative Technology* Energy Utilization: By utilizing * *'s power electronics technology and energy recovery technology, the energy utilization efficiency of electric arc furnaces can be improved.. By reducing energy waste, lowering production costs, and improving smelting efficiency. Automation and Intelligent Control: Introducing automation control systems and artificial intelligence technology can achieve intelligent monitoring and regulation of the operation process of electric arc furnaces, improving production stability and controllability. Application of new materials: By utilizing new high-temperature resistant and conductive materials, the high-temperature resistance performance of electrodes and furnace bodies can be improved, equipment life can be extended, and maintenance costs can be reduced. Future Development TrendsGreen and Environmental Protection: In the future, the development of electric arc furnaces will pay more attention to environmental protection, adopt cleaner smelting technologies, and reduce the impact of emissions on the environment.. Integration and industrial chain optimization: Electric arc furnaces will be more integrated with other production equipment to form a more complete industrial chain, achieving resource utilization and the development of circular economy. Multi energy mixed utilization: Utilizing multiple forms of energy, such as solar and wind energy, combined with the power system to achieve diversified utilization of electric arc furnace energy and improve energy sustainability. Through continuous technological innovation and application expansion, electric arc furnaces will better meet the needs of different industrial fields in the future, making greater contributions to resource utilization and environmental protection.2023-11-08

Innovative Technologies and Future Development Trends of Electric Arc Furnaces!Innovative Technologies and Future Development Trends of Electric Arc Furnaces! As a key technology in the smelting field, electric arc furnace is constantly innovating and improving with the continuous development of technology. The following is a detailed introduction to innovative technologies and future development trends of electric arc furnaces. Innovative Technology* Energy Utilization: By utilizing * *'s power electronics technology and energy recovery technology, the energy utilization efficiency of electric arc furnaces can be improved.. By reducing energy waste, lowering production costs, and improving smelting efficiency. Automation and Intelligent Control: Introducing automation control systems and artificial intelligence technology can achieve intelligent monitoring and regulation of the operation process of electric arc furnaces, improving production stability and controllability. Application of new materials: By utilizing new high-temperature resistant and conductive materials, the high-temperature resistance performance of electrodes and furnace bodies can be improved, equipment life can be extended, and maintenance costs can be reduced. Future Development TrendsGreen and Environmental Protection: In the future, the development of electric arc furnaces will pay more attention to environmental protection, adopt cleaner smelting technologies, and reduce the impact of emissions on the environment.. Integration and industrial chain optimization: Electric arc furnaces will be more integrated with other production equipment to form a more complete industrial chain, achieving resource utilization and the development of circular economy. Multi energy mixed utilization: Utilizing multiple forms of energy, such as solar and wind energy, combined with the power system to achieve diversified utilization of electric arc furnace energy and improve energy sustainability. Through continuous technological innovation and application expansion, electric arc furnaces will better meet the needs of different industrial fields in the future, making greater contributions to resource utilization and environmental protection.2023-11-08 -

Definition and working principle of DC electric arc furnace!Definition and working principle of DC arc furnace! DC arc furnace is a device that uses DC arc to heat and melt metals. It mainly consists of electrodes, arc furnace shell, power supply, and control system. The working principle of a DC arc furnace is as follows:Electrode introduction: Two electrodes, usually carbon electrodes, are set on the arc furnace shell. The electrodes are introduced into the electric arc furnace through a power source. Arc formation: When the electrode comes into contact with a metal material, a voltage is applied through a power source to form an arc discharge. An arc is formed between the electrodes, producing high temperature and strong energy. Heating and melting: The high-temperature energy generated by arc discharge heats and melts metal materials. Molten metal flows by gravity or other means, forming a molten pool. Temperature control: By controlling parameters such as arc current, voltage, and arc length, the temperature of the molten pool and the quality of the molten metal material can be controlled. The working principle of DC electric arc furnace is simple and * *, which makes it widely used in metallurgy, steelmaking, ironmaking and other industries.2023-10-24

Definition and working principle of DC electric arc furnace!Definition and working principle of DC arc furnace! DC arc furnace is a device that uses DC arc to heat and melt metals. It mainly consists of electrodes, arc furnace shell, power supply, and control system. The working principle of a DC arc furnace is as follows:Electrode introduction: Two electrodes, usually carbon electrodes, are set on the arc furnace shell. The electrodes are introduced into the electric arc furnace through a power source. Arc formation: When the electrode comes into contact with a metal material, a voltage is applied through a power source to form an arc discharge. An arc is formed between the electrodes, producing high temperature and strong energy. Heating and melting: The high-temperature energy generated by arc discharge heats and melts metal materials. Molten metal flows by gravity or other means, forming a molten pool. Temperature control: By controlling parameters such as arc current, voltage, and arc length, the temperature of the molten pool and the quality of the molten metal material can be controlled. The working principle of DC electric arc furnace is simple and * *, which makes it widely used in metallurgy, steelmaking, ironmaking and other industries.2023-10-24 -

The advantages and applications of DC arc furnace!The advantages and applications of DC arc furnace! DC electric arc furnaces have many advantages, making them widely used in metallurgy and metal processing industries. Here are several main advantages and application areas:* Energy consumption: DC arc furnaces have the characteristics of high energy efficiency and low energy consumption. Compared to traditional furnaces, it can heat and melt metal materials more quickly, reducing energy consumption. Flexibility and adaptability: DC arc furnaces are suitable for melting and processing various metal materials, such as steel, aluminum, copper, etc. It has high adaptability and can be adjusted and controlled according to different needs and process requirements. Environmental friendliness: The melting process of DC arc furnaces is relatively environmentally friendly. It does not require the use of fuel, reducing the exhaust gas and waste generated during combustion. In addition, DC arc furnaces can also utilize scrap metals for recycling and reuse, reducing resource waste. Precise control: DC arc furnaces have precise temperature control and process parameter adjustment capabilities. By controlling parameters such as current, voltage, and arc length of the arc, precise control of the molten pool temperature and metal material quality can be achieved. DC electric arc furnaces are widely used in industries such as metallurgy, steelmaking, and ironmaking. It can be used for processes such as melting raw materials, alloy preparation, and metal recovery. DC arc furnaces have advantages such as energy consumption, flexibility and adaptability, environmental friendliness, and precise control, providing a reliable and reliable heating and melting equipment for the metal processing and metallurgical industries.2023-10-18

The advantages and applications of DC arc furnace!The advantages and applications of DC arc furnace! DC electric arc furnaces have many advantages, making them widely used in metallurgy and metal processing industries. Here are several main advantages and application areas:* Energy consumption: DC arc furnaces have the characteristics of high energy efficiency and low energy consumption. Compared to traditional furnaces, it can heat and melt metal materials more quickly, reducing energy consumption. Flexibility and adaptability: DC arc furnaces are suitable for melting and processing various metal materials, such as steel, aluminum, copper, etc. It has high adaptability and can be adjusted and controlled according to different needs and process requirements. Environmental friendliness: The melting process of DC arc furnaces is relatively environmentally friendly. It does not require the use of fuel, reducing the exhaust gas and waste generated during combustion. In addition, DC arc furnaces can also utilize scrap metals for recycling and reuse, reducing resource waste. Precise control: DC arc furnaces have precise temperature control and process parameter adjustment capabilities. By controlling parameters such as current, voltage, and arc length of the arc, precise control of the molten pool temperature and metal material quality can be achieved. DC electric arc furnaces are widely used in industries such as metallurgy, steelmaking, and ironmaking. It can be used for processes such as melting raw materials, alloy preparation, and metal recovery. DC arc furnaces have advantages such as energy consumption, flexibility and adaptability, environmental friendliness, and precise control, providing a reliable and reliable heating and melting equipment for the metal processing and metallurgical industries.2023-10-18 -

The working principle and application of electric arc furnace!The working principle and application of electric arc furnace! Electric arc furnace is a common metallurgical equipment used for melting metals and alloys. Its working principle is based on the phenomenon of arc discharge. Below, we will introduce the working principle and application fields of electric arc furnaces. The working principle of an electric arc furnace: An electric arc furnace uses arc discharge to generate high temperature, heating metal materials to their melting point. The basic working principle is as follows:Electrode guidance: An electric arc furnace usually has two electrodes, which are used to transmit current and generate an arc. These electrodes are usually carbon or graphite electrodes, which are guided close to each other but not in direct contact. Arc discharge: Through the power system of an electric arc furnace, current is guided from one electrode to another, forming an arc. The high-temperature heating of the arc heats the surrounding metal materials. Metal melting: High temperature electric arcs heat metal materials to their melting point, melting them into liquid metal. Cooling and casting: Once the metal reaches the desired melting point, the arc closes and the liquid metal begins to cool, allowing for casting or other subsequent processing. Application areas of electric arc furnaces:Metallurgical industry: Electric arc furnaces are widely used in the metallurgical industry for melting various metals, including steel, stainless steel, copper alloys, aluminum alloys, etc. They provide * * and controllable heating methods in metal smelting and casting processes. Scrap metal recycling: Electric arc furnaces are also used for scrap metal recycling, melting waste metal materials (such as scrap steel, scrap aluminum, etc.) into reusable raw materials. Steel production: Electric arc furnaces play a key role in the production of different types of steel, especially in the production of special steel alloys and stainless steel. Ore refining: Some electric arc furnaces are used in the refining process of ore to extract useful metal elements. Laboratory and research: Small electric arc furnaces are also widely used in laboratories and research for alloy development and material testing. Overall, electric arc furnace is a key equipment for high-temperature processing of metals, with a simple and effective working principle, widely used in multiple industrial fields.2023-09-26

The working principle and application of electric arc furnace!The working principle and application of electric arc furnace! Electric arc furnace is a common metallurgical equipment used for melting metals and alloys. Its working principle is based on the phenomenon of arc discharge. Below, we will introduce the working principle and application fields of electric arc furnaces. The working principle of an electric arc furnace: An electric arc furnace uses arc discharge to generate high temperature, heating metal materials to their melting point. The basic working principle is as follows:Electrode guidance: An electric arc furnace usually has two electrodes, which are used to transmit current and generate an arc. These electrodes are usually carbon or graphite electrodes, which are guided close to each other but not in direct contact. Arc discharge: Through the power system of an electric arc furnace, current is guided from one electrode to another, forming an arc. The high-temperature heating of the arc heats the surrounding metal materials. Metal melting: High temperature electric arcs heat metal materials to their melting point, melting them into liquid metal. Cooling and casting: Once the metal reaches the desired melting point, the arc closes and the liquid metal begins to cool, allowing for casting or other subsequent processing. Application areas of electric arc furnaces:Metallurgical industry: Electric arc furnaces are widely used in the metallurgical industry for melting various metals, including steel, stainless steel, copper alloys, aluminum alloys, etc. They provide * * and controllable heating methods in metal smelting and casting processes. Scrap metal recycling: Electric arc furnaces are also used for scrap metal recycling, melting waste metal materials (such as scrap steel, scrap aluminum, etc.) into reusable raw materials. Steel production: Electric arc furnaces play a key role in the production of different types of steel, especially in the production of special steel alloys and stainless steel. Ore refining: Some electric arc furnaces are used in the refining process of ore to extract useful metal elements. Laboratory and research: Small electric arc furnaces are also widely used in laboratories and research for alloy development and material testing. Overall, electric arc furnace is a key equipment for high-temperature processing of metals, with a simple and effective working principle, widely used in multiple industrial fields.2023-09-26 -

The advantages and future development trends of electric arc furnaces!The advantages and future development trends of electric arc furnaces As a metallurgical equipment, electric arc furnaces have significant advantages in metal smelting and material processing, and have potential opportunities and challenges in future development. Advantages: Energy Efficiency: Electric arc furnaces are more energy-efficient compared to traditional smelting methods such as blast furnaces because they can precisely control the heating process and reduce energy waste. Flexibility: Electric arc furnaces can process various metal alloys and scrap metals, making them very flexible in waste recycling and special alloy production. Environmental Protection: Compared to traditional blast furnaces, electric arc furnaces emit less exhaust gas, reducing their adverse impact on the environment and meeting the requirements of sustainable development. Controllability: Electric arc furnaces can achieve precise control of temperature, alloy composition, and other process parameters through precise control systems, improving product quality. Future development trend: Intelligence and automation: In the future, electric arc furnaces will be more intelligent, and remote monitoring and control will be achieved through * *'s automation system to improve production efficiency and safety. New material production: Electric arc furnaces will continue to play a key role in the synthesis and research and development of new materials, especially in high-temperature materials and special alloys. Energy saving technology: With the rise of energy costs and environmental pressures, electric arc furnaces will continue to seek more energy-efficient processes and technologies to reduce their carbon footprint. Waste recycling: Electric arc furnaces will continue to play an important role in the field of waste recycling, promoting circular economy and sustainable development. Overall, electric arc furnaces have significant advantages in metallurgy and material processing, and with the continuous advancement of technology, they will continue to play an important role in future industrial applications. At the same time, in order to address environmental and energy challenges, electric arc furnace technology will continue to evolve to achieve more efficient and sustainable production processes.2023-09-13

The advantages and future development trends of electric arc furnaces!The advantages and future development trends of electric arc furnaces As a metallurgical equipment, electric arc furnaces have significant advantages in metal smelting and material processing, and have potential opportunities and challenges in future development. Advantages: Energy Efficiency: Electric arc furnaces are more energy-efficient compared to traditional smelting methods such as blast furnaces because they can precisely control the heating process and reduce energy waste. Flexibility: Electric arc furnaces can process various metal alloys and scrap metals, making them very flexible in waste recycling and special alloy production. Environmental Protection: Compared to traditional blast furnaces, electric arc furnaces emit less exhaust gas, reducing their adverse impact on the environment and meeting the requirements of sustainable development. Controllability: Electric arc furnaces can achieve precise control of temperature, alloy composition, and other process parameters through precise control systems, improving product quality. Future development trend: Intelligence and automation: In the future, electric arc furnaces will be more intelligent, and remote monitoring and control will be achieved through * *'s automation system to improve production efficiency and safety. New material production: Electric arc furnaces will continue to play a key role in the synthesis and research and development of new materials, especially in high-temperature materials and special alloys. Energy saving technology: With the rise of energy costs and environmental pressures, electric arc furnaces will continue to seek more energy-efficient processes and technologies to reduce their carbon footprint. Waste recycling: Electric arc furnaces will continue to play an important role in the field of waste recycling, promoting circular economy and sustainable development. Overall, electric arc furnaces have significant advantages in metallurgy and material processing, and with the continuous advancement of technology, they will continue to play an important role in future industrial applications. At the same time, in order to address environmental and energy challenges, electric arc furnace technology will continue to evolve to achieve more efficient and sustainable production processes.2023-09-13 -

Advantages and Development Trends of DC Electric Arc Furnace!The advantages and development trends of DC arc furnaces! http://www.ayynd.com/ Keywords:Submerged arc furnace DC ore blast furnace2023-08-14

Advantages and Development Trends of DC Electric Arc Furnace!The advantages and development trends of DC arc furnaces! http://www.ayynd.com/ Keywords:Submerged arc furnace DC ore blast furnace2023-08-14 -

The principle and application of DC electric arc furnace!The principle and application of DC arc furnace! http://www.ayynd.com/ Keywords:Submerged arc furnace DC ore blast furnace2023-08-08

The principle and application of DC electric arc furnace!The principle and application of DC arc furnace! http://www.ayynd.com/ Keywords:Submerged arc furnace DC ore blast furnace2023-08-08 -

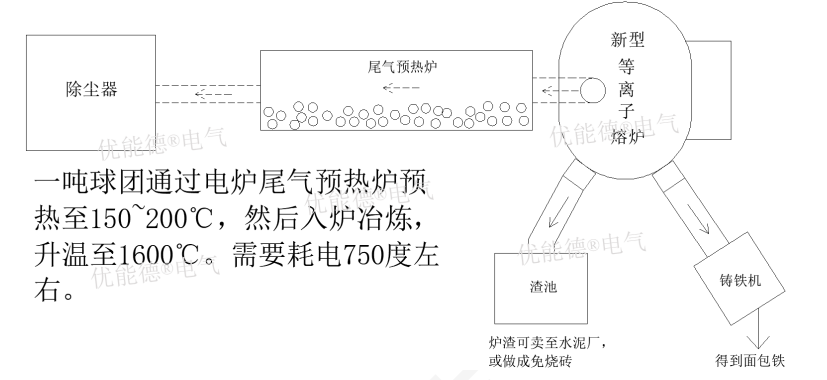

DC plasma furnace is not only green and energy-saving, but also stable and reliable1、 A new process of direct reduction ironmaking for iron containing materials (containing about 40% iron). Copper slag, tin slag, gas cutting slag, ore, grinding wheel ash, oxide scale, dust removal ash, tailings, etc. containing iron are all suitable for use. Smelting produces two types of end products, one is molten iron, and the other is slag (which can be sold to cement plants as clinker). Secondly, this process utilizes the electromagnetic stirring characteristics of a DC plasma electric furnace to increase the fluidity and thermal conductivity of the melt, resulting in uniform temperature and high yield. At the same time, by combining the advantages of a DC furnace with a power factor of up to 0.95-0.98 (arc temperature of 4000 ℃), the melted material can quickly reach its melting point, shorten the smelting time, and obtain high-quality metal. III. Advantages (1) Environmental protection and energy conservation (2) High metal recovery rate (3) High product qualityWe have directly smelted metals or alloys from various ores, solid waste, and hazardous waste, including:1. Iron ore - Iron 7. Titanium ore - Iron, high titanium slag 13. Copper ore - Copper2. Gas cutting slag - Iron 8. Chromium ore, chromium slag - Chromium iron alloy 14. Tin slag - Tin3. Dust removal ash - Iron 9. Manganese ore - Manganese iron alloy 15. Battery lead paste, lead mud - Lead4. Copper slag - Iron 10. Nickel ore, catalyst- Nickel iron alloy 16. Waste circuit boards - copper and precious metals5. Zinc slag - iron 11. Molybdenum nickel ore - molybdenum nickel iron alloy 17. Rare precious metal ores and catalysts - rare precious metals6 Red Mud - Iron 12. Silica, Silicon Mud - Silicon Iron, Metallic SiliconOur company can provide large, medium, and small testing conditions and sites, welcome to process and test materialsOur company's multifunctional DC furnace can smelt various metal and non-metal materials with one set of equipmentA complete set of technical processes, including teaching and training="text align: center;">Microelectronics: 139495145332023-07-20

DC plasma furnace is not only green and energy-saving, but also stable and reliable1、 A new process of direct reduction ironmaking for iron containing materials (containing about 40% iron). Copper slag, tin slag, gas cutting slag, ore, grinding wheel ash, oxide scale, dust removal ash, tailings, etc. containing iron are all suitable for use. Smelting produces two types of end products, one is molten iron, and the other is slag (which can be sold to cement plants as clinker). Secondly, this process utilizes the electromagnetic stirring characteristics of a DC plasma electric furnace to increase the fluidity and thermal conductivity of the melt, resulting in uniform temperature and high yield. At the same time, by combining the advantages of a DC furnace with a power factor of up to 0.95-0.98 (arc temperature of 4000 ℃), the melted material can quickly reach its melting point, shorten the smelting time, and obtain high-quality metal. III. Advantages (1) Environmental protection and energy conservation (2) High metal recovery rate (3) High product qualityWe have directly smelted metals or alloys from various ores, solid waste, and hazardous waste, including:1. Iron ore - Iron 7. Titanium ore - Iron, high titanium slag 13. Copper ore - Copper2. Gas cutting slag - Iron 8. Chromium ore, chromium slag - Chromium iron alloy 14. Tin slag - Tin3. Dust removal ash - Iron 9. Manganese ore - Manganese iron alloy 15. Battery lead paste, lead mud - Lead4. Copper slag - Iron 10. Nickel ore, catalyst- Nickel iron alloy 16. Waste circuit boards - copper and precious metals5. Zinc slag - iron 11. Molybdenum nickel ore - molybdenum nickel iron alloy 17. Rare precious metal ores and catalysts - rare precious metals6 Red Mud - Iron 12. Silica, Silicon Mud - Silicon Iron, Metallic SiliconOur company can provide large, medium, and small testing conditions and sites, welcome to process and test materialsOur company's multifunctional DC furnace can smelt various metal and non-metal materials with one set of equipmentA complete set of technical processes, including teaching and training="text align: center;">Microelectronics: 139495145332023-07-20 -

The advantages and challenges of electric arc furnaces!http://www.ayynd.com/ Keywords:Submerged arc furnace DC ore blast furnace2023-07-20

The advantages and challenges of electric arc furnaces!http://www.ayynd.com/ Keywords:Submerged arc furnace DC ore blast furnace2023-07-20 -

The working principle and application of electric arc furnace!The working principle and application of electric arc furnace! http://www.ayynd.com/ Keywords:Submerged arc furnace DC ore blast furnace2023-07-13

The working principle and application of electric arc furnace!The working principle and application of electric arc furnace! http://www.ayynd.com/ Keywords:Submerged arc furnace DC ore blast furnace2023-07-13 -

What is the difference between DC arc furnace and AC arc furnace?What is the difference between DC arc furnace and AC arc furnace? http://www.ayynd.com/ Keywords:Submerged arc furnace DC ore blast furnace2023-06-09

What is the difference between DC arc furnace and AC arc furnace?What is the difference between DC arc furnace and AC arc furnace? http://www.ayynd.com/ Keywords:Submerged arc furnace DC ore blast furnace2023-06-09

- 中文

-

+86-18537242761