DC plasma furnace is not only green and energy-saving, but also stable and reliable

Update Time: 2023-07-20 Follow: 2365

1、 A new process of direct reduction ironmaking for iron containing materials (containing about 40% iron).

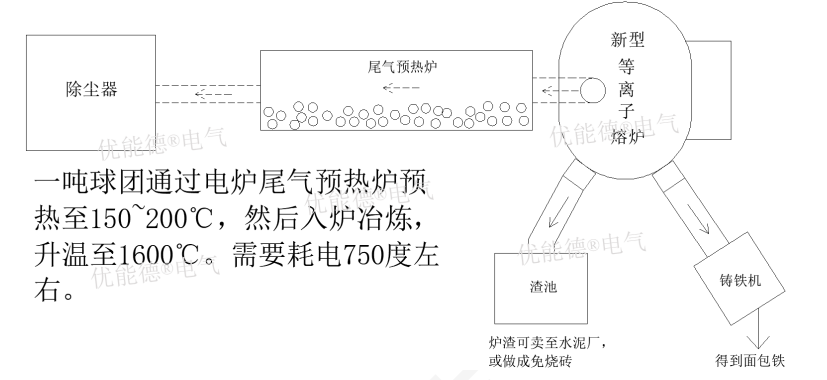

Copper slag, tin slag, gas cutting slag, ore, grinding wheel ash, oxide scale, dust removal ash, tailings, etc. containing iron are all suitable for use. Smelting produces two types of end products, one is molten iron, and the other is slag (which can be sold to cement plants as clinker). Secondly, this process utilizes the electromagnetic stirring characteristics of a DC plasma electric furnace to increase the fluidity and thermal conductivity of the melt, resulting in uniform temperature and high yield. At the same time, by combining the advantages of a DC furnace with a power factor of up to 0.95-0.98 (arc temperature of 4000 ℃), the melted material can quickly reach its melting point, shorten the smelting time, and obtain high-quality metal.

III. Advantages (1) Environmental protection and energy conservation (2) High metal recovery rate (3) High product quality

We have directly smelted metals or alloys from various ores, solid waste, and hazardous waste, including:

1. Iron ore - Iron 7. Titanium ore - Iron, high titanium slag 13. Copper ore - Copper

2. Gas cutting slag - Iron 8. Chromium ore, chromium slag - Chromium iron alloy 14. Tin slag - Tin

3. Dust removal ash - Iron 9. Manganese ore - Manganese iron alloy 15. Battery lead paste, lead mud - Lead

4. Copper slag - Iron 10. Nickel ore, catalyst

- Nickel iron alloy 16. Waste circuit boards - copper and precious metals5. Zinc slag - iron 11. Molybdenum nickel ore - molybdenum nickel iron alloy 17. Rare precious metal ores and catalysts - rare precious metals

6 Red Mud - Iron 12. Silica, Silicon Mud - Silicon Iron, Metallic Silicon

Our company can provide large, medium, and small testing conditions and sites, welcome to process and test materials

Our company's multifunctional DC furnace can smelt various metal and non-metal materials with one set of equipment

A complete set of technical processes, including teaching and training="text align: center;">Microelectronics: 13949514533