Working principle of electric arc furnace and its impact on power quality

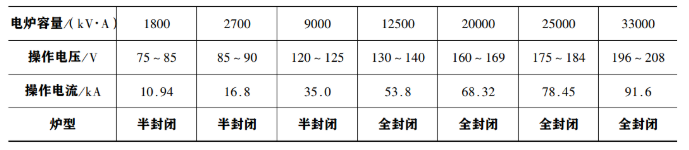

In order to understand the reasons for the impact of electric arc furnaces on power quality and efficiency, it is necessary to provide a brief introduction to the special characteristics of electric arc furnace equipment. 1、 Classification and working principle of electric arc furnaces Electric arc furnace is a type of electric furnace that uses electric arc energy to smelt metals. The electric arc furnaces used in industry can be divided into three categories: * * category is direct heating type, where the arc occurs between a dedicated electrode rod and the melted furnace material, and the furnace material is directly heated by the arc. Mainly used for steelmaking, it is also used for melting iron, copper, refractory materials, refining molten steel, etc. The second type is indirect heating, in which an arc occurs between two dedicated electrode rods, and the furnace material is subjected to the radiation heat of the arc, used for melting copper, copper alloys, etc. This type of furnace has high noise and poor melting quality, and has gradually been replaced by other types of furnaces. The third type is called a mineral thermal furnace, which uses high resistivity ore as raw material, and the lower part of the electrode is usually buried in the furnace material during operation. The heating principle is to utilize both the heat generated by the resistance of the charge when current passes through it, as well as the heat generated by the arc between the electrode and the charge. So it is also known as an arc resistance furnace. 2、 Composition equipment of electric arc furnace Furnace transformer The transformer used for arc steelmaking should be able to adjust the voltage and current separately according to the smelting requirements, and be able to withstand the impact of working short-circuit current. The selection of rated voltage for electric furnace transformers should consider many factors. If the primary voltage is higher, the system reactance will be smaller and the short-circuit capacity will be larger, which can reduce flicker, but it will require an increase in the cost of distribution equipment. If the secondary voltage is higher, the power factor is higher and the electrical efficiency is higher, but the arc is longer, the furnace wall loss is faster, and the overall efficiency decreases. Generally, the secondary side of electric furnace transformers has low voltage (tens to hundreds of volts) and high current (thousands to tens of thousands of amperes). To ensure the different requirements for electrical power in each melting stage, the secondary voltage of the transformer should be adjustable within the range of 50%~70%, so it is designed in a multi-stage adjustable form. The adjustment methods include transformation, on load tap changer, etc. For transformers with a capacity less than 10MVA, no-load switching can be performed; For capacities above 10MVA, on load voltage regulation should generally be used. There are also three-phase tap devices installed separately, and each phase can be adjusted separately to ensure the balance of three-phase thermal energy in the furnace. Compared with ordinary power transformers, electric furnace dedicated transformers have the following characteristics: a. They have a greater overload capacity; b. Has high mechanical strength; c. Has a large short-circuit impedance; d. How many secondary voltage levels are there; e. Has a large voltage conversion ratio; f. The secondary voltage is low while the current is high. The capacity ratio of electric furnace transformers to electric arc furnaces is generally 0.4~1.2MVA/t. The current control of an electric arc furnace is achieved by the switching of the high-voltage side winding tap of the electric arc furnace transformer and the lifting and lowering of the electrodes. Reactor In order to stabilize the arc and short-circuit current, a reactance capacity of approximately 35% of the transformer capacity is required to be connected in series to the main circuit of the transformer. Large electric arc furnace transformers have the required reactance value and do not require external reactors; Transformers with a reactance less than 10MVA do not meet the requirements and require an external reactor on the primary side. The structural characteristic of a reactor is that even through short-circuit current, the iron core does not undergo magnetic saturation. The reactor can be installed inside the electric furnace transformer, which is called an internal type; It can also be made into an independent reactor installed outside the transformer, called an external attachment type. Electric furnace transformers generally need to be connected in series with reactors, so that the sum of the short-circuit impedance of the transformer and the reactance of the reactor reaches the standard value of 0.33-0.5 (based on the rated capacity of the electric furnace transformer). Electric furnace transformers with a capacity of less than 10MVA are sometimes equipped with series reactors on their high-voltage side to reduce short-circuit current and stabilize arcs. For larger capacity electric furnace transformers, their own leakage reactance is already large enough, and there is no need to connect reactors in series. High voltage circuit breaker The requirements for high-voltage circuit breakers in steelmaking electric arc furnaces are: large breaking capacity; Allow frequent actions; Easy to maintain and have a long service life. The load of the electric arc resistance furnace is stable and operates continuously. High voltage circuit breakers with high or low oil are commonly used. Circuit breakers for steelmaking electric arc furnaces often trip, and sulfur hexafluoride circuit breakers, electromagnetic air circuit breakers, vacuum circuit breakers, etc. are commonly used. Current Transformer

2022-03-08

The operation process of industrial silicon smelting with all coal and the calculation of various parameters of the ore blast furnace2022-03-08

The operation process of industrial silicon smelting with all coal and the calculation of various parameters of the ore blast furnace2022-03-08 Process and Operation of High Carbon Manganese Iron Production by Electric Furnace Method2022-03-08

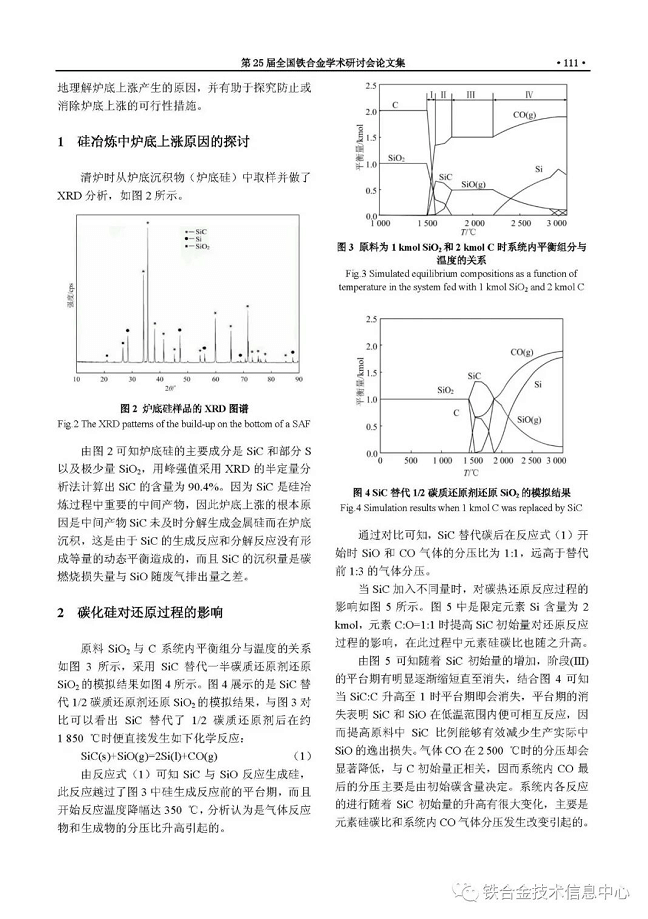

Process and Operation of High Carbon Manganese Iron Production by Electric Furnace Method2022-03-08 Exploration into the Rise of Furnace Temperature in Industrial Silicon Smelting Production工业硅炉冶炼生产炉度上涨的探究292022-03-08

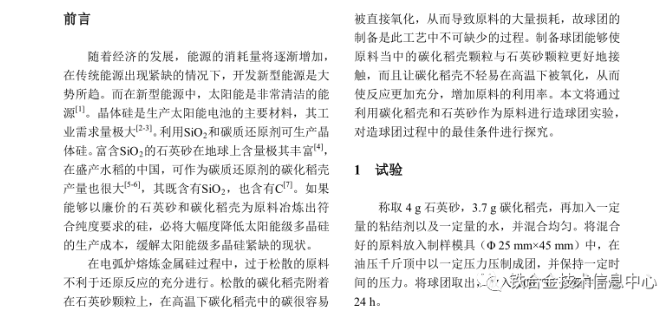

Exploration into the Rise of Furnace Temperature in Industrial Silicon Smelting Production工业硅炉冶炼生产炉度上涨的探究292022-03-08 Exploration on the preparation conditions of pellets in the process of preparing high-purity silicon using carbonized rice husks**页第二页第三页2022-03-08

Exploration on the preparation conditions of pellets in the process of preparing high-purity silicon using carbonized rice husks**页第二页第三页2022-03-08 The effect and influence of slag alkalinity on furnace condition in silicon manganese smelting2022-03-08

The effect and influence of slag alkalinity on furnace condition in silicon manganese smelting2022-03-08 The world's largest DC arc furnace: 420 tons2022-03-08

The world's largest DC arc furnace: 420 tons2022-03-08 Technical operating procedures for high carbon ferrochrome一、产品质量要求 高碳铬铁按碳含量的不同分为四个牌号,其化学成分应符合表表中的规定。种类牌 号化 学 成 分 (%)Cr CSiPS范围ⅠⅡⅠⅡⅠⅡⅠⅡ不小于不 大 于2022-03-08

Technical operating procedures for high carbon ferrochrome一、产品质量要求 高碳铬铁按碳含量的不同分为四个牌号,其化学成分应符合表表中的规定。种类牌 号化 学 成 分 (%)Cr CSiPS范围ⅠⅡⅠⅡⅠⅡⅠⅡ不小于不 大 于2022-03-08 Electric furnace steelmaking is the process of refining slag, and you must understand the relevant knowledge of slag!2022-03-08

Electric furnace steelmaking is the process of refining slag, and you must understand the relevant knowledge of slag!2022-03-08 Low carbon manganese iron smelting process technology2022-03-08

Low carbon manganese iron smelting process technology2022-03-08 Knowledge | About the judgment of electrodes and furnace materials in the production process of mineral thermal furnaces2022-03-08

Knowledge | About the judgment of electrodes and furnace materials in the production process of mineral thermal furnaces2022-03-08 Process and principle of electric furnace smelting high carbon ferrochrome2022-03-08

Process and principle of electric furnace smelting high carbon ferrochrome2022-03-08 Working principle of electric arc furnace and its impact on power qualityIn order to understand the reasons for the impact of electric arc furnaces on power quality and efficiency, it is necessary to provide a brief introduction to the special characteristics of electric arc furnace equipment. 1、 Classification and working principle of electric arc furnaces Electric arc furnace is a type of electric furnace that uses electric arc energy to smelt metals. The electric arc furnaces used in industry can be divided into three categories: * * category is direct heating type, where the arc occurs between a dedicated electrode rod and the melted furnace material, and the furnace material is directly heated by the arc. Mainly used for steelmaking, it is also used for melting iron, copper, refractory materials, refining molten steel, etc. The second type is indirect heating, in which an arc occurs between two dedicated electrode rods, and the furnace material is subjected to the radiation heat of the arc, used for melting copper, copper alloys, etc. This type of furnace has high noise and poor melting quality, and has gradually been replaced by other types of furnaces. The third type is called a mineral thermal furnace, which uses high resistivity ore as raw material, and the lower part of the electrode is usually buried in the furnace material during operation. The heating principle is to utilize both the heat generated by the resistance of the charge when current passes through it, as well as the heat generated by the arc between the electrode and the charge. So it is also known as an arc resistance furnace. 2、 Composition equipment of electric arc furnace Furnace transformer The transformer used for arc steelmaking should be able to adjust the voltage and current separately according to the smelting requirements, and be able to withstand the impact of working short-circuit current. The selection of rated voltage for electric furnace transformers should consider many factors. If the primary voltage is higher, the system reactance will be smaller and the short-circuit capacity will be larger, which can reduce flicker, but it will require an increase in the cost of distribution equipment. If the secondary voltage is higher, the power factor is higher and the electrical efficiency is higher, but the arc is longer, the furnace wall loss is faster, and the overall efficiency decreases. Generally, the secondary side of electric furnace transformers has low voltage (tens to hundreds of volts) and high current (thousands to tens of thousands of amperes). To ensure the different requirements for electrical power in each melting stage, the secondary voltage of the transformer should be adjustable within the range of 50%~70%, so it is designed in a multi-stage adjustable form. The adjustment methods include transformation, on load tap changer, etc. For transformers with a capacity less than 10MVA, no-load switching can be performed; For capacities above 10MVA, on load voltage regulation should generally be used. There are also three-phase tap devices installed separately, and each phase can be adjusted separately to ensure the balance of three-phase thermal energy in the furnace. Compared with ordinary power transformers, electric furnace dedicated transformers have the following characteristics: a. They have a greater overload capacity; b. Has high mechanical strength; c. Has a large short-circuit impedance; d. How many secondary voltage levels are there; e. Has a large voltage conversion ratio; f. The secondary voltage is low while the current is high. The capacity ratio of electric furnace transformers to electric arc furnaces is generally 0.4~1.2MVA/t. The current control of an electric arc furnace is achieved by the switching of the high-voltage side winding tap of the electric arc furnace transformer and the lifting and lowering of the electrodes. Reactor In order to stabilize the arc and short-circuit current, a reactance capacity of approximately 35% of the transformer capacity is required to be connected in series to the main circuit of the transformer. Large electric arc furnace transformers have the required reactance value and do not require external reactors; Transformers with a reactance less than 10MVA do not meet the requirements and require an external reactor on the primary side. The structural characteristic of a reactor is that even through short-circuit current, the iron core does not undergo magnetic saturation. The reactor can be installed inside the electric furnace transformer, which is called an internal type; It can also be made into an independent reactor installed outside the transformer, called an external attachment type. Electric furnace transformers generally need to be connected in series with reactors, so that the sum of the short-circuit impedance of the transformer and the reactance of the reactor reaches the standard value of 0.33-0.5 (based on the rated capacity of the electric furnace transformer). Electric furnace transformers with a capacity of less than 10MVA are sometimes equipped with series reactors on their high-voltage side to reduce short-circuit current and stabilize arcs. For larger capacity electric furnace transformers, their own leakage reactance is already large enough, and there is no need to connect reactors in series. High voltage circuit breaker The requirements for high-voltage circuit breakers in steelmaking electric arc furnaces are: large breaking capacity; Allow frequent actions; Easy to maintain and have a long service life. The load of the electric arc resistance furnace is stable and operates continuously. High voltage circuit breakers with high or low oil are commonly used. Circuit breakers for steelmaking electric arc furnaces often trip, and sulfur hexafluoride circuit breakers, electromagnetic air circuit breakers, vacuum circuit breakers, etc. are commonly used. Current Transformer2022-03-08

Working principle of electric arc furnace and its impact on power qualityIn order to understand the reasons for the impact of electric arc furnaces on power quality and efficiency, it is necessary to provide a brief introduction to the special characteristics of electric arc furnace equipment. 1、 Classification and working principle of electric arc furnaces Electric arc furnace is a type of electric furnace that uses electric arc energy to smelt metals. The electric arc furnaces used in industry can be divided into three categories: * * category is direct heating type, where the arc occurs between a dedicated electrode rod and the melted furnace material, and the furnace material is directly heated by the arc. Mainly used for steelmaking, it is also used for melting iron, copper, refractory materials, refining molten steel, etc. The second type is indirect heating, in which an arc occurs between two dedicated electrode rods, and the furnace material is subjected to the radiation heat of the arc, used for melting copper, copper alloys, etc. This type of furnace has high noise and poor melting quality, and has gradually been replaced by other types of furnaces. The third type is called a mineral thermal furnace, which uses high resistivity ore as raw material, and the lower part of the electrode is usually buried in the furnace material during operation. The heating principle is to utilize both the heat generated by the resistance of the charge when current passes through it, as well as the heat generated by the arc between the electrode and the charge. So it is also known as an arc resistance furnace. 2、 Composition equipment of electric arc furnace Furnace transformer The transformer used for arc steelmaking should be able to adjust the voltage and current separately according to the smelting requirements, and be able to withstand the impact of working short-circuit current. The selection of rated voltage for electric furnace transformers should consider many factors. If the primary voltage is higher, the system reactance will be smaller and the short-circuit capacity will be larger, which can reduce flicker, but it will require an increase in the cost of distribution equipment. If the secondary voltage is higher, the power factor is higher and the electrical efficiency is higher, but the arc is longer, the furnace wall loss is faster, and the overall efficiency decreases. Generally, the secondary side of electric furnace transformers has low voltage (tens to hundreds of volts) and high current (thousands to tens of thousands of amperes). To ensure the different requirements for electrical power in each melting stage, the secondary voltage of the transformer should be adjustable within the range of 50%~70%, so it is designed in a multi-stage adjustable form. The adjustment methods include transformation, on load tap changer, etc. For transformers with a capacity less than 10MVA, no-load switching can be performed; For capacities above 10MVA, on load voltage regulation should generally be used. There are also three-phase tap devices installed separately, and each phase can be adjusted separately to ensure the balance of three-phase thermal energy in the furnace. Compared with ordinary power transformers, electric furnace dedicated transformers have the following characteristics: a. They have a greater overload capacity; b. Has high mechanical strength; c. Has a large short-circuit impedance; d. How many secondary voltage levels are there; e. Has a large voltage conversion ratio; f. The secondary voltage is low while the current is high. The capacity ratio of electric furnace transformers to electric arc furnaces is generally 0.4~1.2MVA/t. The current control of an electric arc furnace is achieved by the switching of the high-voltage side winding tap of the electric arc furnace transformer and the lifting and lowering of the electrodes. Reactor In order to stabilize the arc and short-circuit current, a reactance capacity of approximately 35% of the transformer capacity is required to be connected in series to the main circuit of the transformer. Large electric arc furnace transformers have the required reactance value and do not require external reactors; Transformers with a reactance less than 10MVA do not meet the requirements and require an external reactor on the primary side. The structural characteristic of a reactor is that even through short-circuit current, the iron core does not undergo magnetic saturation. The reactor can be installed inside the electric furnace transformer, which is called an internal type; It can also be made into an independent reactor installed outside the transformer, called an external attachment type. Electric furnace transformers generally need to be connected in series with reactors, so that the sum of the short-circuit impedance of the transformer and the reactance of the reactor reaches the standard value of 0.33-0.5 (based on the rated capacity of the electric furnace transformer). Electric furnace transformers with a capacity of less than 10MVA are sometimes equipped with series reactors on their high-voltage side to reduce short-circuit current and stabilize arcs. For larger capacity electric furnace transformers, their own leakage reactance is already large enough, and there is no need to connect reactors in series. High voltage circuit breaker The requirements for high-voltage circuit breakers in steelmaking electric arc furnaces are: large breaking capacity; Allow frequent actions; Easy to maintain and have a long service life. The load of the electric arc resistance furnace is stable and operates continuously. High voltage circuit breakers with high or low oil are commonly used. Circuit breakers for steelmaking electric arc furnaces often trip, and sulfur hexafluoride circuit breakers, electromagnetic air circuit breakers, vacuum circuit breakers, etc. are commonly used. Current Transformer2022-03-08